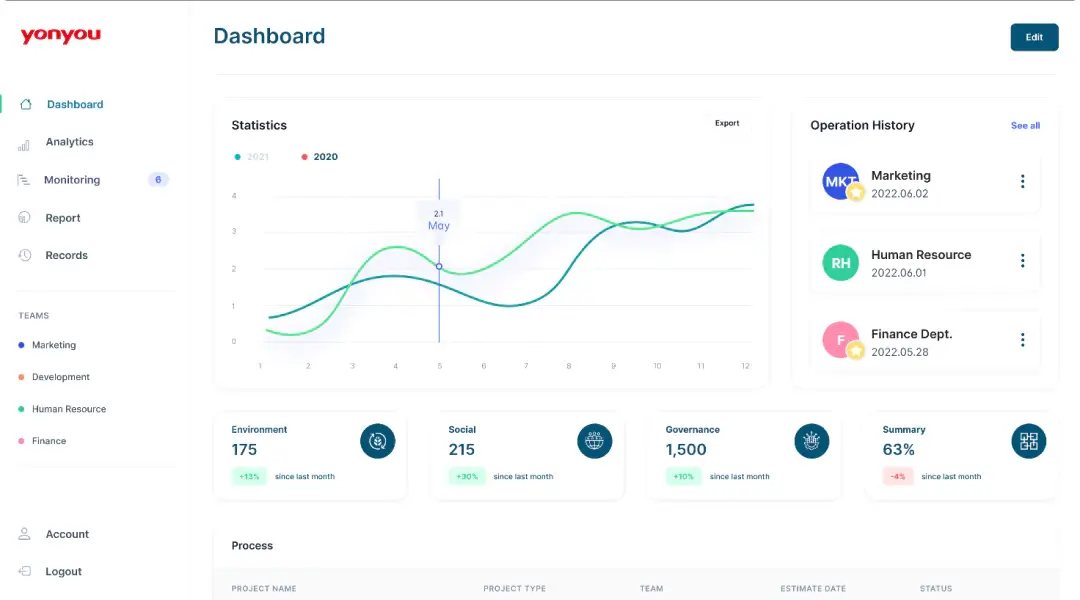

优化运营流程

用友如何应对

制造业挑战

用友ERP系统通过提供多语言支持,实现无缝翻译和沟通,从而解决制造业面临的挑战。系统集成了应收账款(AR)和销售管理模块,可实时跟踪订单付款情况,并通过智能提醒功能对未结清的发票进行预警,确保财务透明度并降低财务风险。

痛点

- 缺乏可视性和控制力

- 低效的生产规划与排程

- 高库存成本

- 质量控制问题

- 供应链中断

解决方案

- 通过用友物联网网络的互联设备与传感器,实现生产流程的实时可视化与全面监控。

- 利用先进的数据分析与预测工具,优化生产计划、资源调配及排程,提高运营效率并确保准时交付。

精细化库存管理,降低库存持有成本,同时保障生产所需的物料供应充足。

- 集成质量管理系统(QMS)与数据分析工具,实现质量问题的早期识别与预防,提升产品一致性与合规性。

结合供应商关系管理(SRM)模块,增强供应链协同能力,提高供应链的稳定性与响应速度。

强大 优势

降低成本

优化材料使用和生产计划,最大限度减少浪费。

更优的资源分配

确保人力和设备的高效利用。

提升准时交付率

帮助企业按时满足客户需求和交付期限。

提高可见性

清晰展现生产计划和进度,确保全流程透明可控。

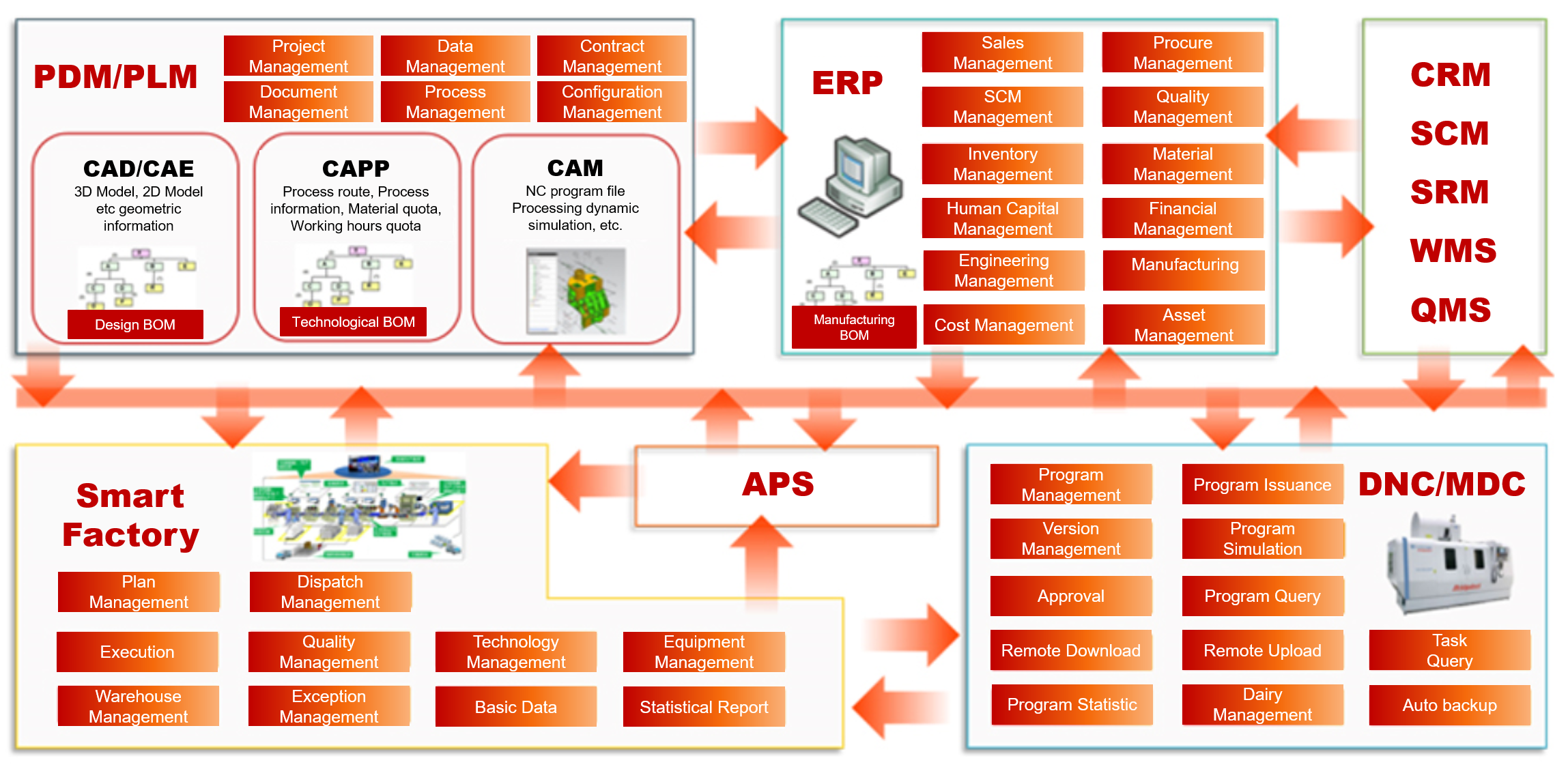

Key Areas & Features

构建您的智能工厂

AloT 平台

生产与制造

质量管理

售后服务

产品生命周期管理 (PLM)

AloT 平台

智能工厂

应用程序开发

物联网平台

工业大脑

安全生产

智能工厂

智能工厂

- 从工厂车间的传感器实现实时数据可视化

- 基于设备数据的预测性维护警报

- 根据实时生产状况优化生产计划

应用程序开发

应用程序开发

- 在用友一体化平台内创建全新的功能

- 管理独特的生产流程或定制的高级报表工具,以满足数据分析需求

物联网平台

物联网平台

- 机器和机器人上的传感器提供更精准的生产状况视图

- 监测设备健康状况、追踪库存流动,并根据传感器数据优化能源消耗

工业大脑

工业大脑

- 分析来自生产线、设备及供应链等多个来源的大量数据

- 识别趋势、预测潜在问题,并为生产流程优化提供建议

- ERP 可推荐调整生产计划、资源分配,甚至触发预防性维护以避免停机

安全生产

安全生产

- 帮助识别潜在设备故障,防止事故发生

- 通过停止机器运行或警告工人潜在危险,以防止不安全操作

生产与制造

工程变更管理

生产规划

生产管理

车间管理

工程变更管理

工程变更管理

- 变更发起与请求管理

- 建立审核与批准变更的工作流程

- 识别组件和材料(BOM 和库存)的变更,更新生产流程,评估成本影响,并管理文件修订,确保获取最新信息

生产规划

生产规划

- 预测产品的市场需求,确保生产与客户需求匹配

- 确保原材料供应充足,以满足生产订单需求

- 管理原材料采购、生产制造及产品交付的周期,以提高供应链效率

生产管理

生产管理

- 统筹日常生产运营,包括工单调度、资源分配及生产进度跟踪

车间管理

车间管理

- 实时监控和控制车间生产活动

质量管理

质量检验

质量追溯

质量检验

质量检验

- 制定针对不同产品或生产阶段的检验计划

- 记录未达质量标准的产品情况

- 允许电子记录检验数据,包括照片、视频或自动检测设备的传感器读数

- 生成检验趋势、缺陷率报告,并识别生产流程中的改进空间

质量追溯

质量追溯

- 通过序列号跟踪每个批次或单个产品的生产流程

- 电子存储所有与质量相关的文件

- 基于生产批次或序列号识别所有受影响的产品

- 通过清晰的审计记录,确保符合行业法规和质量标准

售后服务

服务设定

安装交付

服务管理

服务设定

服务设定

- 创建详细的服务描述

- 确定提供每项服务所需的技能和资源

- 建立服务定价模型,并预设维护计划

安装交付

安装交付

- 根据客户需求、技术人员的可用性和行程安排安装及服务预约

- 跟踪并监控现场服务技术人员的进度

- 协调产品或备件的配送至客户地点,并追踪交付过程

服务管理

服务管理

- 跟踪保修期限,管理服务合同,并自动发送提醒

- 提供平台让客户提交服务请求,跟踪其状态,并接收维修或维护进度更新

- 采集现场技术人员的数据,包括执行的工作内容和耗时

- 收集客户反馈,以优化服务体验

产品生命周期管理 (PLM)

文档管理

集中式数据存储库

变更管理

文档管理

文档管理

- 处理产品数据,如 CAD 图纸、技术规格、物料清单 (BOM) 和工程变更单 (ECO)

集中式数据存储库

集中式数据存储库

- 管理产品的整个生命周期,从最初的概念与设计,到开发、生产、服务及报废处理。

变更管理

变更管理

- 监控并记录产品在其生命周期内的所有变更

深受400多家企业信赖

客户案例

携手成功, 共创未来

BDA Group

制造业案例研究

亚太聚氨酯制造(APU)

制造业案例研究

Aice Group Holdings

制造与批发分销行业案例研究

Founded in 2014 and headquartered in Singapore, Aice Group Holdings specializes in trading and manufacturing.

新鹏联众汽车

制造业案例研究

Xinpeng Lianzhong Automotive Co Ltd was incorporated back in 2010, as a joint venture between Shanghai Xinpeng Industrial Co Ltd and SSDT Technology (a subsidiary of